Serving as the eyes of a skilled operator

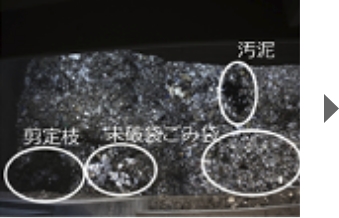

At a waste incineration plant, it is important to stabilize combustion to ensure compliance with exhaust gas emission standards and efficient power generation. Accordingly, in the waste bunker, where waste is stored temporarily before it goes to the incinerator, waste is stirred with a crane to homogenize its properties before incineration, instead of simply being stored there.

Previously, an operator had to visually identify the properties of waste from above the bunker and operate the crane manually. Finding the alternative for the eyes of the operator was a major challenge in the development for the operatorless plant operation system.

An automatic crane system using a waste identification AI

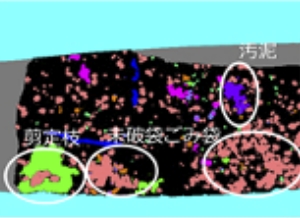

The automatic crane system with a waste identification AI uses a camera to observe the status of the waste in the bunker, uses AI to recognize conditions including how the waste has been stirred, and determines appropriate crane operations within the bunker using advanced control system. EBARA Environmental Plant developed a waste identification AI using deep learning jointly with Ridge-i Inc., which has an established reputation for its image analysis technologies. Using AI to identify waste has enabled actions that were difficult with conventional automatic cranes, including:- Selecting waste that is suitable for incineration and loading it into the incinerator- Identifying and appropriately handling special waste (waste that could affect equipment or combustion if it is loaded into the incinerator in mass). This has enabled operatorless plant operations to account for 90% of all operations.

Moving forward, we will expand the use of this automatic crane system with AI and use AI to control combustion in incinerators. We will then aim to automate the operation of incinerators by combining the results achieved through the identification of waste loaded into incinerators and the automated combustion control of incinerators.

EBARA Environmental Plant wins Excellence Award at the Deep Learning Business Awards

The world of deep learning has moved from the research phase to the phase where it is being implemented in society and in business. Excellent projects applying deep learning in business are recognized by the Deep Learning Business Awards, a program jointly sponsored by Nikkei Cross Trend and Nikkei x TECH.

EBARA Environmental Plant is developing systems for operations using AI and other state-of-the-art technologies, with the goal of automating the operation of incinerators and developing next-generation waste treatment facilities that are not dependent on the experience-based knowledge of operatorshuman workers to enable more stable waste treatment. In recognition of the automatic crane system with waste identification AI that we developed as part of the above initiative, we were granted the Excellence Award at the Deep Learning Business Awards in October 2019.

At EBARA Environmental Plant, we will apply AI and other state-of-the-art technologies, from the perspective of facility operators to provide even more secure, more reliable waste treatment services and contribute to the creation of sustainable local communities.