Waste Treatment Facilities and Energy Plants

- Grate-type Incineration System

- Fluidized-Bed-type Incineration System

- Gasification Technologies

- Boilers

- Manufacturing

Fluidized-Bed-type Incineration System

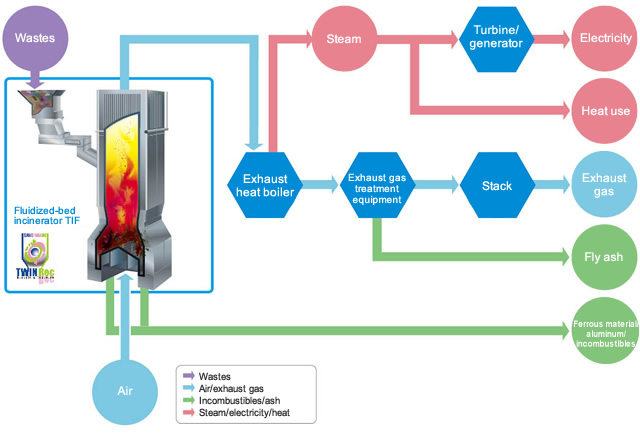

■ Twin interchanging fluidized-bed (TIF®) incineration system*

The fluidized-bed incineration systems take advantage of the thermal capacity of hot fluid sand to quickly and uniformly combust the materials to be treated. Therefore, the systems are able to treat a wide range of waste, including municipal solid waste, low calorific value waste like waste liquids and sludges, and high -calorific value waste like shreddeddiscarded tires or waste plastics. It is also suitable for mixed firing using the refuse dug up from final disposal sites, night soil sludgeexcreta or sewage sludge.

The greatest feature of our fluidized-bed incineration technology is its original internally swirling feature. The swirling effect stirs waste, sludge and other substances to ensure treatment at a very high mixture rate. Non-combustibles are stably discharged by the flow of the fluid sand. This means that the system requires no mechanically operated parts. Other characteristics include a low ignition loss of non-combustibles and the recovery of iron, aluminum and other metallic substances in an unoxidized state. In addition, the internal desulfurization and dehydrochlorination features that are unique to fluidized-bed systems will help reduce the consumption of chemicals and costs for flue gas treatment.

The Introduction of a system with low excess air combustion and flueexhaust gas recirculation leads to high efficiency power generation.

A small amount of combustibles that stay in the incinerator means that incinerator operations can be quickly and safely stopped in the event of emergency.

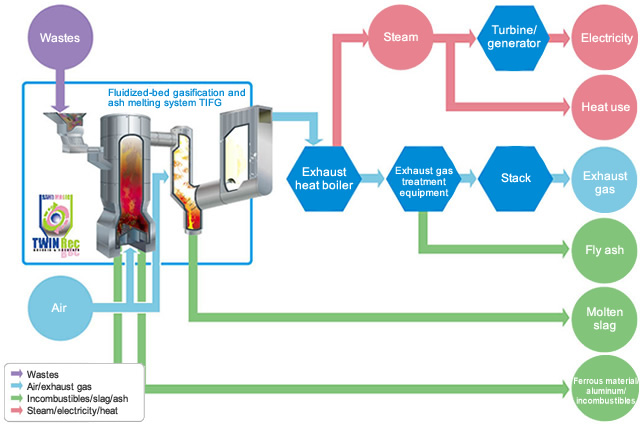

■ TIFG® fluidized-bed gasification and ash melting system*

An effective option in a future situation where final disposal sites are feared to be in short supply will be to process incineration ash into molten slag to use it as a construction material.

Our fluidized-bed gasification and ash melting system features the combination of our proven fluidized-bed technology with a swirling ash melting furnace. It uses the energy derived from waste to melt ash and recover it in the form of a slag so that it can be effectively utilized.

It is equipped with the TIF® incineration system's internally swirlingcirculating feature. Recovering iron, aluminum and other substances in an unoxidized state, it helps reduce the volume of waste disposed of indisposed in landfills.

Low excess air combustion at a high temperature in the swirling ash melting furnace reduces dioxin emissions. High boiler efficiency ensures it is suitable for high efficiency power generation. Capable of co-firing with ash from other facilities, sludges, refuse dug up from final disposal sites and other materials, it helps reduce land disposal and aids the restoration of landfill disposal sites.