Waste Treatment Facilities and Energy Plants

Boilers

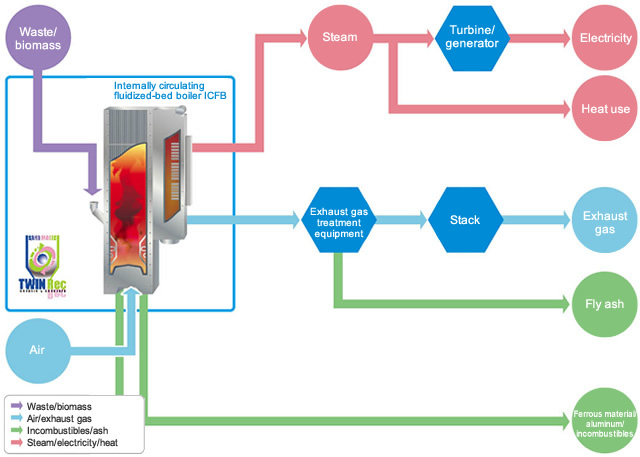

■ Internally circulating fluidized-bed boiler (ICFB®)

Following a recent increase in the use of renewable energy, power generation using woody biomass such as thinned timber is attracting attention.

The internally circulating fluidized-bed boiler (ICFB®) is one of our original technologies. It was developed as a boiler for high efficiency power generation from coal, plastic waste, shredded tires and other fuels. Since its initial development, it has been improved many times. It is now also suitable for high efficiency woody biomass electric power generation.

In-bed heat transfer tubes are set in a heat recovery chamber that is arranged separately from the main combustion chamber. That opens the way for high efficiency energy recovery while avoiding corrosion and the worn-out of heat transfer tubes. Its original heat transfer control feature maintains a constant combustion temperature and controls the quantity of steam. That helps quickly respond to changes in fuel properties and load changes. It can also be operated under low-load conditions.

The interior of the furnace is kept negatively pressurized through balanced draft operations. This means that fuel does not need to be finely crushed and that there are no worries about the leakage of combustion gases. Of course, the non-combustibles contained in the fuels can be stably discharged from the system by the internally circulating mechanism.